OUR MANUFACTURING PROCESS

CORRUGATION

This is the basic process that gives us the corrugated

board. It is made on a long series of linked machines called a corrugating

line. The corrugating medium, which will become the wavy middle

layer in the typical three-layer corrugated board “sandwich,”

is pre-heated and steamed so its temperature nearly reaches the

boiling point of water, 212ºF. This softens the natural ingredients

in the paperboard, making it easier to form into flutes.

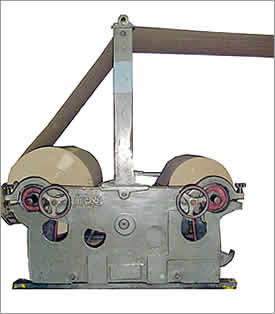

The web, or long sheet of paper unwinding from

the roll, is drawn between a pair of gear-like cylinders called

corrugating rolls. This shapes the paper into a series of precise

waves. Glue is applied to the tips of these flutes on one side —

just the right amount, and at just the right places — and

the flute tips are pressed against a flat liner. This creates a

singleface web, a continuous sheet of flat paper with fluted paper

glued to it.

To make single wall corrugated board, the exposed

flutes of the singleface web have glue applied to them, and they’re

pressed against a second flat liner.

The continuous web of corrugated board is now

so stiff that it can’t be rolled up. Instead, it’s cut

into flat sheets, just the right size for making the boxes that

have been ordered. The sheets are then stacked and set aside so

the glue can dry properly.

|